Perkara : Promosi Lantikan Pengedar Malaysia

Jadi pengedar kami sekarang dan dapatkan harga promosi.

Harga Jual(SRP) = RM21.00(pc)

Harga Pengedar (Biasa) = RM15.00

Harga Promosi(Dec08) = RM10.00

Min.Order = 48pcs

[Caption.iT - Picture Captions]

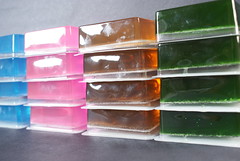

Detailed Product Description (Soap Base)

Detailed Product Description (Soap Base)

The first write-up assumes you can just go to a store and buy the ingredients. The second only assumes you have some animals you will be butchering and that you have been burning wood fires and cleverly saved the ashes.

A small plastic dishpan, about 10" x 12"

A glass or enamel 2-quart saucepan

1 can of lye (sodium hydroxide), 12 ounces

3 pounds of lard

Plastic gloves [really; use eye-protection too]

Water

1. Pour 3 cups of very cold water (refrigerate water overnight first) into the 2-quart saucepan.

2. Slowly and carefully add the lye, a little bit at a time, stirring it with the a wooden or plastic utensil. (Use plastic gloves for this; test them for holes first.) Do not breathe the vapor or lean over the container or have children nearby. Above all _use no metal_. The mixture will get very hot. In olden days, a sassafras branch was used to stir, imparting a fragrance and insect deterrent for mosquitoes, lice, fleas and ticks.

3. Let cool at least one hour in a safe place. Meanwhile, the unwrapped lard should be warming up to room temperature in the plastic dishpan.

4. Slowly and carefully, pour the lye solution into the dishpan with the lard. The lard will melt. Mix thoroughly, at least 15 minutes, until it looks like thick pudding.

5. Let it set until the next morning, then cut it into bars. It will get harder after a few days. Then package.

If you wish to make soap based on olive oil, use about 48 ounces. It may need to harden for a week.

Saponification is a very big chemical word for the rather complex but easy to create soap making reaction. Saponification is what happens when a fatty acid meets an alkali. When fats or oils, which contain fatty acids are mixed with a strong alkali, the alkali first splits the fats or oils into their two major parts fatty acids and glycerin. After this splitting of the fats or oils, the sodium or potassium part of the alkali joins with the fatty acid part of the fat or oils. This combination is then the potassium or sodium salt of the fatty acid. As we said at the start, this is soap.

The lye solution was obtained by placing wood ashes in a bottomless barrel set on a stone slab with a groove and a lip carved in it. The stone in turn rested on a pile of rocks. To prevent the ashes from getting in the solution a layer of straw and small sticks was placed in the barrel then the ashes were put on top. The lye was produced by slowly pouring water over the ashes until a brownish liquid oozed out the bottom of the barrel. This solution of potash lye was collected by allowing it to flow into the groove around the stone slab and drip down into a clay vessel at the lip of the groove.

Some colonists used an ash hopper for the making of lye instead of the barrel method. The ash hopper, was kept in a shed to protect the ashes from being leached unintentionally by a rain fall. Ashes were added periodically and water was poured over at intervals to insure a continuous supply of lye. The lye dripped into a collecting vessel located beneath the hopper.

[Use whatever you have available or can make.]

The cleaning of fats is called rendering and is the smelliest part of the soap making operation. Animal fat, when removed from the animals during butchering, must be rendered before soap of any satisfactory quality can be made from it. This rendering removes all meat tissues that still remain in the fat sections. Fat obtained from cattle is called tallow while fat obtained from pigs is called lard.

If soap is being made from grease saved from cooking fires, it is also rendered to remove all impurities that have collected in it. The waste cooking grease being saved over a period of time without the benefits of refrigeration usually become rancid, so this cleaning step is very important to make the grease sweeter. It will result in a better smelling soap. The soap made from rancid fats or grease will work just as well as soap made from sweet and clean fats but not be as pleasant to have around and use.

To render, fats and waste cooking grease are placed in a large kettle and an equal amount of water is added. Then the kettle is placed over the open fire outdoors. Soap making is an outside activity. The smell from rendering the fats is too strong to wish in anyone's house. The mixture of fats and water are boiled until all the fats have melted. After a longer period of boiling to insure completion of melting the fats, the fire is stopped and into the kettle is placed another amount of water about equal to the first amount of water. The solution is allowed to cool down and left over night. By the next day the fats have solidified and floated to the top forming a layer of clean fat. All the impurities being not as light as the fat remain in water underneath the fat.

You may have observed this in your own kitchen. When a stew or casserole containing meat has been put in the refrigerator, you could see the next day the same fat layer.

To make hard soap, common salt is thrown in at the end of the boiling. If this is done a hard cake of soap forms in a layer at the top of the pot. As common salt may be expensive and hard to get, it is not usually wasted to make hard soap. Common salt is more valuable to give to the livestock and the preserving of foods. Soft soap works just as well as hard and for these reasons the colonists, making their own soap, did not make hard soap bars.

In towns and cities where there were soap makers making soap for sale, the soap could be converted to the hard soap by the addition of salt. As hard bars it will be easier to store and transport. Hard bars produced by the soap maker were often scented with oils such as lavender, wintergreen, or caraway and were sold as toilet soap to persons living in the cities or towns.

Hard soap is not cut into small bars and wrapped as has been familiar. Soap made by the soap makers is poured into large wooden frames and removed when cooled and hard.

The amount of soap a customer wants can be cut from the large bar. Soap is sold usually by the pound. Small wrapped bars were not available until the middle of the 19th century [nor maybe shortly after the end of the 20th].

A Pennsylvania Dutch recipe once carefully warned that a sassafras stick was the only kind of implement suitable for stirring the mixture [see Hulda Clark comment above re sassafras] and the stirring must be done always in the same direction [?].

Potash is the residue remaining after all the water has been driven off from the lye solution obtained from the leaching of wood ashes. Pearlash is then made from the potash by baking it in a kiln until all the carbon impurities were burned off. The fine, white powder remaining was the Pearlash....

Your one stop solution for handmade soaps and soap supplies.

|

|